Images of Science

Many of the images can not only be seen online, but are also available as large format, framed pictures (1.20 m x 1.20 m). Here you will find information on the rental conditions for the travelling exhibition.

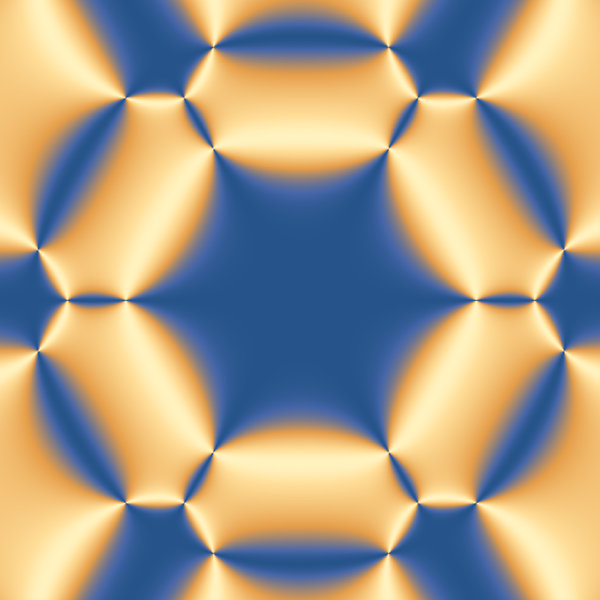

A closer look reveals that our image was created by duplication: The original result was mirrored on the longitudinal axis.

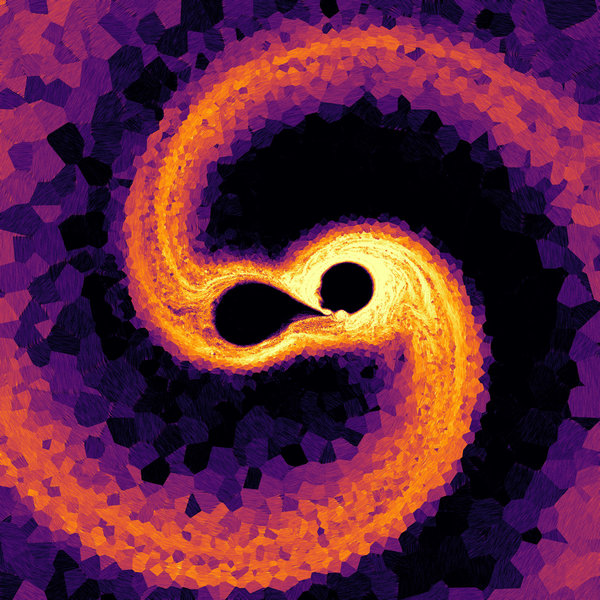

One day, magnetic vortex structures, like the one shown here, could help to process data particularly quickly. These structures arise in magnetic wafers of one micrometre in diameter and just a few nanometres thick. Unlike in a standard permanent magnet, the individual magnetic moments, which can be imagined as tiny rod magnets, order themselves in these wafers: their magnetic field forms needles which project from the front (red) or back (blue) of the disk and can thus store the zero or one of a data bit. Short magnetic pulses flip the needles from one direction to the other with lightening speed. The simulation shows the transition with the needles to the front (red) and back (blue). The magnetic moments in the orange and green areas only project slightly from the image plane.

The SIL in the photograph appears to hover in the air as a sphere; however, this impression is misleading: the hemispherical lens and the objective of the interferometer are reflected in the object slide, a metal mirror, on which the lens is placed.

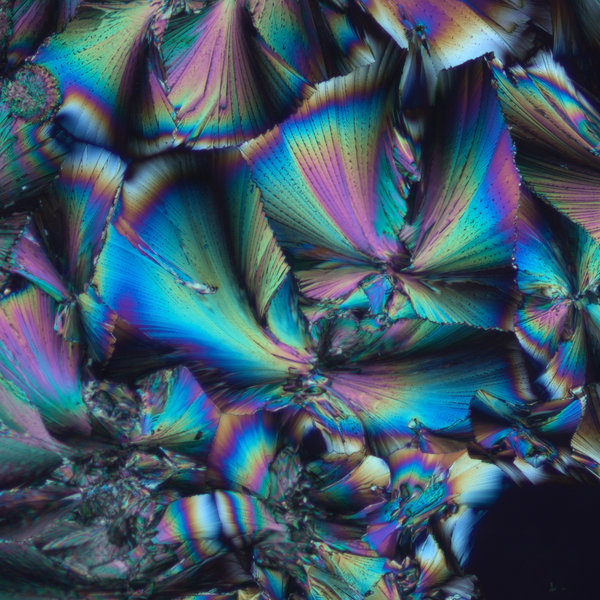

Although it was already in use in ancient China, cast iron is to this day a popular subject of current basic research. As an alloy with spheroidal graphite, it is as malleable as steel, but significantly less complicated and less expensive to produce. Also known as spheroidal iron, it is used for the production of pipes, in the automotive industry or in reactor technology, for example. The image shows the microstructure of the alloy: the spherical nodules of carbon appear as round islets; the fine network of lines indicates where different grains of materials collide. Max Planck researchers are studying the effect of this microstructure on material properties. They would like to be able to tailor the structure and thus the properties of the material to different applications.